Gzm2145 Mining Conical Ball Mill

GZM Series Conical Ball Mill_Yantai Jinhao Mining Machinery Co.,

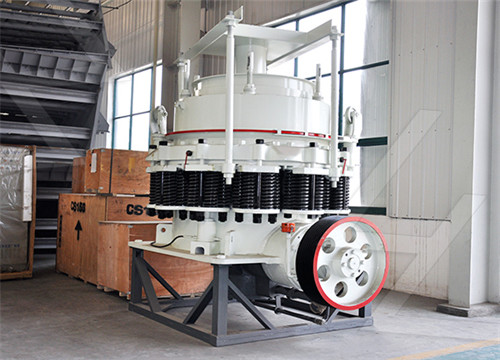

GZM Series Conical Ball Mill-Yantai Jinhao Mining Machinery Co., Ltd.-ProductDetails1.Ituseslarge-diameterdoublerowself-aligningbearing,haslongservicelife

GZM Series Conical Ball Mill---Yantai Huali Mining Machinery Co.,

2. The discharge end adopts conical structure to reinforce the mill, naturally grade steel balls and ensure fine ground material granularity. 3. It adopts integral steel chassis, and

Ball Mills Mineral ProcessingMetallurgy

An Energy-T75 Size Reduction Model for Ball Mills SpringerLink

2022年12月22日This is a size-based crushing test using a conical ball mill to establish an energy-size reduction relationship [Shi, 2014]. Experiments were conducted with five mono-sized feed samples including 300–600 μm, 600–1180 μm, 1180–2000 μm, 2000–2800 μm, and 2800–4000 μm from two types of ores, quartz, and calcite, respectively.

Used Ball-mills For Sale

OUTOKUMPU Ball Mill, 1.45MW (1945 HP) Manufacturer: OUTOKUMPU View Details UNUSED FLSMIDTH MINERALS 20' x 33' (6m x 10m) Ball Mill, 6700 kw (8981 HP) Inventory ID: 6C-LIC01 UNUSED FLSMIDTH MINERALS 20' x 33' (6m x 10m) Ball Mill, 6700 kW (8981 HP) Manufacturer: FLSMIDTH View Details HARDINGE 6' x 9' (1.83m x

Energy-Size Reduction of Magnetite-Calcite Binary Mixture in

promote the break of hard anthracite in hardgrove mills [26]. (4) t 10 = M ˜ 1−exp ˚ −f mat ×E ˛ t 10 = M ˜ 1−exp ˚ −3.6pd(1−q)E cs ˛ A×b = 3.6M ⋅p⋅d(1−q) (5) However, in Chinese laboratories, it is conical ball mills that are commonly used, yet there are few reports on the grinding behavior of multi-component minerals

Ball Mills Mineral ProcessingMetallurgy

2017年2月13日A ball mill efficiently operated performs a wide variety of services. In small milling plants, where simplicity is most essential, it is not economical to use more than single stage crushing, because the Steel-Head Ball or Rod Mill will take up to 2″ feed and grind it to the desired fineness.

Hardinge Conical Ball Mill Mineral ProcessingMetallurgy

2015年12月22日The Conical Mill is now being used in all parts of the World, having substituted these latter types of machines in the grinding of ores and other materials. Hardinge Conical Ball Mills are used to do the work of any combination of the above machines and will produce the desired results, depending upon the size and type of mill

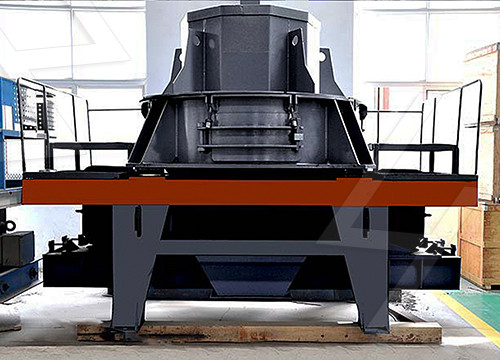

Conical Ball Mill for Sale WetDry Conical Ball Mill Energy

Conical ball mill is a common ball grinding mill in mineral processing production. Conical ball mill can grind all kinds of ores and other materials, not only can be used as a pre-grinding machine for pre-grinding, but also as a grinding equipment in the

Industrial Ball Mills: Steel Ball Mills and Lined Ball Mills Orbis

Steel Ball MillsLined Ball Mills. Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800’s. The basic construction of a ball mill is a cylindrical container with journals at its axis. The cylinder is filled with grinding media (ceramic or metallic balls or rods

Used Conical Mills for sale. Comil equipmentmore Machinio

Up to 32" diameter Conical, PolygonalRound Welded USED Manufacturer: EuropeanAsian Major Line Components as follows: Max od: 813 mm Max w/t: 38 mm Mx lgth: 16 meters Mill type: Rd Pipe/ Conical /Polygonal Poles Year built new: 2006 Rockville Centre, NY, USA Click to Request Price Trusted Seller Quadro 194FS 3103 USED

Ball Mill RETSCH powerful grinding and homogenization

RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each application. The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest

Grinding mills in Canada Nelson Machinery buy mining

Explore our huge range of ball mills, SAG mills, roller mills, vertical mills, and miscellaneous grinding mills. Conical Mill (3) Gears (10) Jar Rolls (1) Liners (5) Rod Mill (13) Roller Mill (2) ShellHeads (3) Steel (1) Placer Mining; Agglomerators; AgitatorsMixers; Air Compressors; AssayLaboratory; Blowers; Buildings

Ball Mill Explained saVRee

There are three main stages to mineral processing in the mining industry. These are: Comminution (crushing and grinding). Beneficiation (separation and concentration). Smelting and refining. Ball mills are employed in the comminution stage as grinding machines (

Ball Mill for Sale Mining and Cement Milling Equipment

Production capacity: 300t/d Processed material: Silver ore Input size: ≤25mm Equipment: Wet grate type silver ore ball mill, wet overflow type silver ore ball mill, jaw crusher, cone crusher, flotation machine, concentrator, filter press. Auxiliary equipment: Linear vibration screen, cyclone.

Appendix A Report on Alkaline Carbonate Leaching at

Homestake Mining Company is a major uranium mining and milling operation near Grants, New Mexico. The Mill, originally built in 1958, had a capacity of 1650 tons per day. With subsequent improvements and the addition of the adjacent Homestake New Mexico Partners mill, the HMC mill is currently rated at about 3500 tons per day.

AMIT 135: Lesson 6 Grinding Circuit Mining Mill Operator

Objectives. At the end of this lesson students should be able to: Explain the grinding process. Distinguish between crushing and grinding. Compare and contrast different type of equipment and their components used for grinding. Identify key variables for process control. Design features of grinding equipment (SAG, BALL and ROD MILLS)

An Energy-T75 Size Reduction Model for Ball Mills SpringerLink

2022年12月22日This is a size-based crushing test using a conical ball mill to establish an energy-size reduction relationship [Shi, 2014]. Experiments were conducted with five mono-sized feed samples including 300–600 μm, 600–1180 μm, 1180–2000 μm, 2000–2800 μm, and 2800–4000 μm from two types of ores, quartz, and calcite, respectively.

Energy-Size Reduction of Magnetite-Calcite Binary Mixture in

promote the break of hard anthracite in hardgrove mills [26]. (4) t 10 = M ˜ 1−exp ˚ −f mat ×E ˛ t 10 = M ˜ 1−exp ˚ −3.6pd(1−q)E cs ˛ A×b = 3.6M ⋅p⋅d(1−q) (5) However, in Chinese laboratories, it is conical ball mills that are commonly used, yet there are few reports on the grinding behavior of multi-component minerals

Grinding mills in Canada Nelson Machinery buy mining

Explore our huge range of ball mills, SAG mills, roller mills, vertical mills, and miscellaneous grinding mills. Conical Mill (3) Gears (10) Jar Rolls (1) Liners (5) Rod Mill (13) Roller Mill (2) ShellHeads (3) Steel (1) Placer Mining; Agglomerators; AgitatorsMixers; Air Compressors; AssayLaboratory; Blowers; Buildings

Conical Ball Mill for Sale WetDry Conical Ball Mill Energy

Conical ball mill is a common ball grinding mill in mineral processing production. Conical ball mill can grind all kinds of ores and other materials, not only can be used as a pre-grinding machine for pre-grinding, but also as a grinding equipment in the

Ball Mills Best of 2023 911Metallurgist

Ball Mills Best 2023 Models. Showing all 16 results. Laboratory Ball Mill (Ball or Rod) Benchtop Ball Mill. US $ 12,000. Planetary Ball Mill. US $ 9,000. Floor Mounted Laboratory Grinding Mill. US $ 11,000. Small Vibratory Ball Mill

AMIT 135: Lesson 7 Ball MillsCircuits Mining Mill Operator

Objectives. At the end of this lesson students should be able to: Explain the role of ball mill in mineral industry and why it is extensively used. Describe different types of ball mill design. Describe the components of ball mill. Explain their understanding of ball mill operation. Explain the role of critical speed and power draw in design

Industrial Ball Mills: Steel Ball Mills and Lined Ball Mills Orbis

Steel Ball MillsLined Ball Mills. Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800’s. The basic construction of a ball mill is a cylindrical container with journals at its axis. The cylinder is filled with grinding media (ceramic or metallic balls or rods

Ball Mill RETSCH powerful grinding and homogenization

The variety of grinding modes, usable volumes and available grinding tool materials make ball mills the perfect match for a vast range of applications. CoolingHeating Mixer Mill MM 500 control Material feed size*: <= 10 mm Final fineness*: ~ 0.1 µm Vibrational frequency: 3 30 Hz (180 -1800 min-1) Product details Nanoscale Grinding

Used Conical Mills for sale. Comil equipmentmore Machinio

Up to 32" diameter Conical, PolygonalRound Welded USED Manufacturer: EuropeanAsian Major Line Components as follows: Max od: 813 mm Max w/t: 38 mm Mx lgth: 16 meters Mill type: Rd Pipe/ Conical /Polygonal Poles Year built new: 2006 Rockville Centre, NY, USA Click to Request Price Trusted Seller Quadro 194FS 3103 USED

Floor Mounted Laboratory Grinding Mill 911Metallurgist

This Grinding Mill is fully enclosed with sound dampening material for a quiet workplace. The sheet metal steel fabrication provides full enclosure around the main frame and door. The yoke (grinding cylinder) is totally balance and vibration-free in

BALL MILL GRINDER Industrial Ball Mill For Sale

The use of hydraulic bearing brings the ball mill a large bearing capacity, small starting force, and high motion rate. The shaft adopts steel casting, and the cylinder is inlaid with wear-resistant lining plates. The lining plate adopts detachable stepped lining plates or corrugated lining plates. Competitive Price

AMIT 135: Lesson 6 Grinding Circuit Mining Mill Operator

Conical shell for “graded” ball charge and optimal size reduction Only available in small and intermediate sizes Efficient “high reduction ratio grinding’ SSR Mill (Svedala Rubber Roller mill) Wet or dry Overflow and grate discharge Light and fabricated construction Ready assembled on steel frame Easy to move Limited in size (max. diameter 2.4 m)

Ball Mill Ball Mills WetDry Grinding DOVE

The working principle is simple, impact and attrition size reduction take place as the ball drops from near the top of the rotating hollow cylindrical shell of the Ball Mill. The output materials will be feed to the processing and recovery machines. Ball Mill set

Ball Mill For Gold Mining AGICO Gold Ball Mill For Sale

Gold ball mill is a high-efficiency and fine-grinding ball mill grinder, which is widely used in mining, chemical industry, building materials industry, and other fields. It is available in gold dressing plants to process refractory As-bearing gold ore. At the same time, it can also be applied to the secondary utilization of gold ore tailings.

- 水泥厂用碳酸钙石粉与电厂脱硫用碳酸钙石粉的区别

- Blower Grinder 4r 3216 Raymond Mill 4r3216 Cg

- 河北铝矾土磨粉设备

- Crusher Manufacturer For Dolomite Padang Indonesia

- 人造石英石破碎

- V T Corp Pvt Ltd Concentrate Plant

- Does Skull Crusher Support Zune

- 湖北松滋石头碎石机采石场

- Defect On Rolls Inrolling Mills

- 仕名立磨

- 粉碎混泥土缝爆

- 赞皇磨粉机

- 南京二手挖掘机设备转让

- 张翼鹏 东辽

- Buildwell Brick Machine Copper Rock Slag As Raw Material