Gold Concentrate Flotation Separation Of Mining Cheap

Processing Gold Ore by Flotation Mineral ProcessingMetallurgy

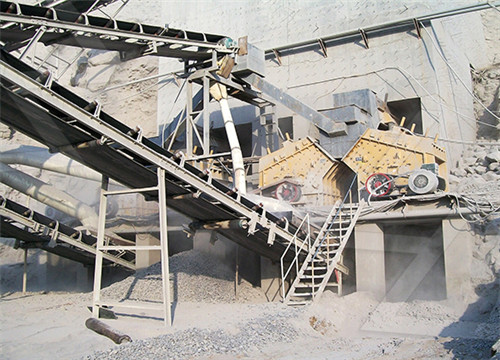

Application of Flotation to Gold OreUse of Flotation OilsGold Recovery by FlotationGold Ore Crushing PlantEffect of Roasting

A test on a sample, crushed to pass a screen of 120 holes per linear inch, containing $37 gold and 4.8% copper, gave a recovery by flotation alone of 90% of the gold and 98.5% of the copper, but left $8 gold in the tailing. The concentrate carried 44% insoluble matter, which could be reduced by re-treatment. A different oil (eucalyptus) would have

Gold Flotation Mineral ProcessingMetallurgy

根据热度为您推荐•反馈

Separation efficiency improvement of a low grade copper

additional pyrite (containing gold) to the copper concentrate, thereby improving gold recovery from the operation. Zheng, CrawfordManton (2009) presented details on how

The Separation of Carbonaceous Matter from Refractory Gold Ore

2021年11月1日As a pre-treatment method of refractory gold ore, carbonaceous matter (C-matter) flotation was investigated with multi-stage flotation by rougher, scavenger, and

Gold processing Mining and concentrating Britannica

Gold can be freed from these ores or concentrates by treating them with various oxidizing processes. The most common method is to roast gold-bearing minerals at temperatures

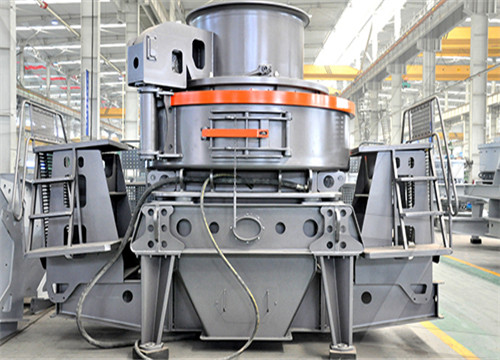

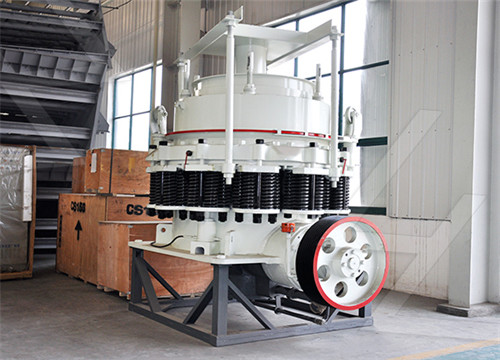

The Definitive Guide to Flotation Separation Fote

2023年2月15日The flotation separation process mainly includes: (1) Grind the ore finely by the ball mill or rod mill to dissociate useful minerals from gangue minerals. (2)

Gold Flotation Concentrate LinkedIn

2016年12月29日Process Introduction The flotation method is a widely used technique for the recovery of gold from gold-containing copper ores, base metal ores, copper-nickel

The Common Gold Mining Process Froth Flotation Method

2019年12月2日The froth flotation method used in the gold mining mainly includes: After washing and classifying, the mineral is mixed evenly by agitation tank drum and sent to

5 Types Of Gold Flotation Reagent Mining-pedia

2021年3月5日Gold flotation reagents can be divided into 5 types: collectors, foaming agents, inhibitors, activators, and pH regulators. Flotation reagent is one of the key factors affecting the flotation of gold

Beneficiation of the gold bearing ore by gravity and flotation

2012年1月25日Gold concentration usually consists of gravity separation, flotation, cyanidation, or the combination of these processes. The choice among these processes depends on the mineralogical characterization and gold content of the ore. Recently, the recovery of gold using gravity methods has gained attention because of low cost and

The effect of polysaccharide depressant xanthan gum on the flotation

2020年10月1日The Geer gold mining area in Qinghai Province, China, has yielded gold resources of 60 t (Au grade of 3.2 g/t) to date, and the whole exploration project is expected to become a gold reserves of 100 t, making it a super-large gold mine. the average grade and recovery of gold concentrate are 18% and 77.02%, respectively, so

Effects of particle size on flotation performance in the separation

2019年2月15日In contrast to the cumulative recovery of gold with various size fractions, the greatest D.I. value was appeared with the coarse size fraction of −100 + 74 μm, which indicated that the worse selective enrichment of gold in the copper concentrate was of the −100 + 74 μm size fraction during the separation flotation process, possibly since

(PDF) A Brief Review of Auriferous Sulphide Flotation

2020年8月5日The preferential concentration of valuable metals such as gold in arsenopyrite in comparison to pyrite drives current research interest, despite challenges associated with separating arsenopyrite...

The Separation of Carbonaceous Matter from Refractory Gold

2021年11月1日As a pre-treatment method of refractory gold ore, carbonaceous matter (C-matter) flotation was investigated with multi-stage flotation by rougher, scavenger, and cleaner stages. Different dosages of kerosene and MIBC (4-Methyl-2-pentanol) were applied and the optimum dosage was selected by testing in each flotation stage. With the

The Common Gold Mining Process Froth Flotation Method

2019年12月2日The froth flotation method used in the gold mining mainly includes: After washing and classifying, the mineral is mixed evenly by agitation tank drum and sent to the flotation machine. The goldmine generally uses sodium carbonate as the regulator, so that the gold is floated.

METHODS OF ENSURING THE INCREASE IN THE QUALITY OF

agent to enhance flotation beneficiation ores containing gold; multi-component magnetic separation. Introduction The Republic of Uzbekistan is one of the countries rich in natural resources. Almost all elements of the periodic table in its depth, most of them in industrial collector done; a gold concentrate with a gold content of 32.0 g

Gold Flotation Concentrate LinkedIn

2016年12月29日Flotation is considered to be the most cost-effective method for concentrating gold. Flotation process maximizes the enrichment of gold into sulfide minerals. The tailings can be directly...

Mercury and artisanal and small-scale golding mining: Review of

2 之Mintek has developed a process called iGoli Mercury-free Gold Extraction Process that can be used to extract gold from 0.1 % gold concentrate to produce 99.90 percent gold product.

Mining and processing plant engineering design

ESFC, an international company, offers financing and engineering design for mining and processing plants under an EPC contract, including research, development of individual technical solutions, etc.

5 Gold Extraction Methods to Improve Your Recovery Rate

2023年2月15日Flotation separation for the gold extraction process According to different physical and chemical properties of different types of gold ores, flotation separation utilizes various reagents to make the gold attached to the bubbles then scraping these gold particles from blades to get the concentrate.

Magnetic Separators For Mineral Processing JXSC Mining

2023年3月9日Magnetic separators are widely used in the beneficiation of ferrous metal ores, non-ferrous and rare metal ores; the recovery and purification of media in heavy media beneficiation; the removal of impurities from non-metallic ore raw materials; the removal of iron-containing impurities in crushing; recycling scrap steel from smelting waste residue

Gold Processing Plant Prominer (Shanghai) Mining Technology

These gold professionals are specifically in gold processing through various beneficiation technologies, for gold ore of different characteristics, such as flotation, cyanide leaching, gravity separation, etc., to achieve the processing plant of

Cip System, Cip Process, Cip Gold Processing Xinhai

Xinhai CIP Production Line has helped hundreds of mines to get gold. Our gold production process and gold recovery methods are based on rich experience. marketing@ytxinhai. 0086 . Language.

Beneficiation of the gold bearing ore by gravity and flotation

2012年1月25日Gold concentration usually consists of gravity separation, flotation, cyanidation, or the combination of these processes. The choice among these processes depends on the mineralogical characterization and gold content of the ore. Recently, the recovery of gold using gravity methods has gained attention because of low cost and

The effect of polysaccharide depressant xanthan gum on the flotation

2020年10月1日The Geer gold mining area in Qinghai Province, China, has yielded gold resources of 60 t (Au grade of 3.2 g/t) to date, and the whole exploration project is expected to become a gold reserves of 100 t, making it a super-large gold mine. the average grade and recovery of gold concentrate are 18% and 77.02%, respectively, so

Effects of particle size on flotation performance in the separation

2019年2月15日In contrast to the cumulative recovery of gold with various size fractions, the greatest D.I. value was appeared with the coarse size fraction of −100 + 74 μm, which indicated that the worse selective enrichment of gold in the copper concentrate was of the −100 + 74 μm size fraction during the separation flotation process, possibly since

(PDF) A Brief Review of Auriferous Sulphide Flotation

2020年8月5日The preferential concentration of valuable metals such as gold in arsenopyrite in comparison to pyrite drives current research interest, despite challenges associated with separating arsenopyrite...

The Separation of Carbonaceous Matter from Refractory Gold

2021年11月1日As a pre-treatment method of refractory gold ore, carbonaceous matter (C-matter) flotation was investigated with multi-stage flotation by rougher, scavenger, and cleaner stages. Different dosages of kerosene and MIBC (4-Methyl-2-pentanol) were applied and the optimum dosage was selected by testing in each flotation stage. With the

The Common Gold Mining Process Froth Flotation Method

2019年12月2日The froth flotation method used in the gold mining mainly includes: After washing and classifying, the mineral is mixed evenly by agitation tank drum and sent to the flotation machine. The goldmine generally uses sodium carbonate as the regulator, so that the gold is floated.

METHODS OF ENSURING THE INCREASE IN THE QUALITY OF

agent to enhance flotation beneficiation ores containing gold; multi-component magnetic separation. Introduction The Republic of Uzbekistan is one of the countries rich in natural resources. Almost all elements of the periodic table in its depth, most of them in industrial collector done; a gold concentrate with a gold content of 32.0 g

Gold Flotation Concentrate LinkedIn

2016年12月29日Flotation is considered to be the most cost-effective method for concentrating gold. Flotation process maximizes the enrichment of gold into sulfide minerals. The tailings can be directly...

Mercury and artisanal and small-scale golding mining: Review of

2 之Mintek has developed a process called iGoli Mercury-free Gold Extraction Process that can be used to extract gold from 0.1 % gold concentrate to produce 99.90 percent gold product.

Mining and processing plant engineering design

ESFC, an international company, offers financing and engineering design for mining and processing plants under an EPC contract, including research, development of individual technical solutions, etc.

Magnetic Separators For Mineral Processing JXSC Mining

2023年3月9日Magnetic separators are widely used in the beneficiation of ferrous metal ores, non-ferrous and rare metal ores; the recovery and purification of media in heavy media beneficiation; the removal of impurities from non-metallic ore raw materials; the removal of iron-containing impurities in crushing; recycling scrap steel from smelting waste residue

RP-4 Gold Shaker Table Sale 911Metallurgist

RP-4 Shaker Table. US$ 6,000 $ 5,550. The RP-4 shaker table is the most widely used and most successful gold gravity shaking concentrating table worldwide, used by small and large mining operations and hobbyists.

Ultimate Guide of Gold Flotation Process Mining-pedia

2020年3月20日For gold flotation process, crushing and grinding process is necessary and a huge amount of flotation reagent must be consumed. Therefore, gold flotation process means higher cost than gravity separation and amalgam treatment. Gold Flotation Case. 1000t/d Gold Flotation Plant in Shandong, China. Project Background